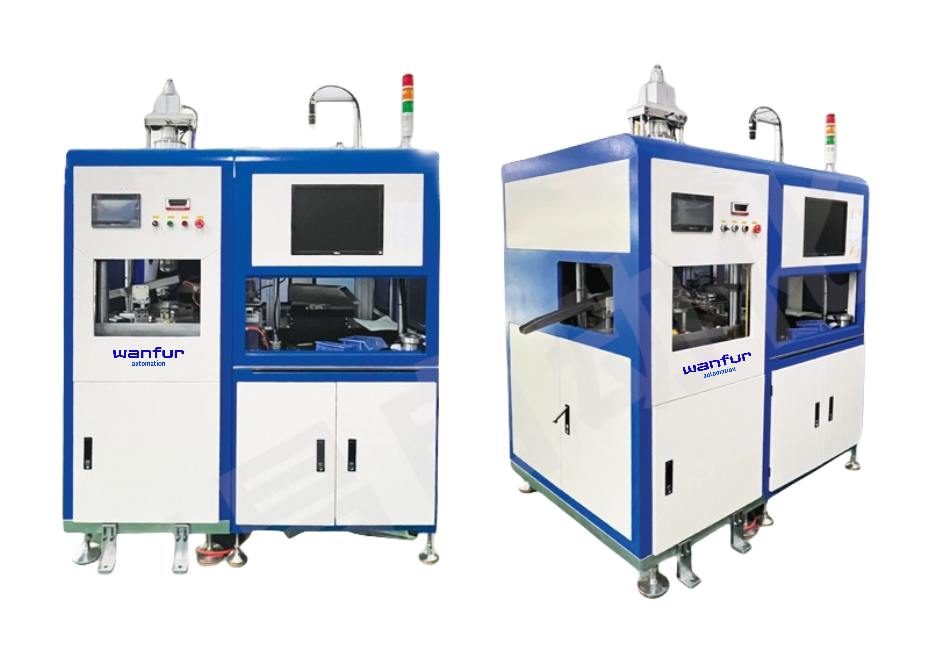

Metal Vibration Welding Machine

Wanfur has two types of Metal Vibration Welding Machines: one is semi-automatic rotary friction welding, another one is fully automatic loading and unloading rotating friction welding.

Metal Vibration Welding Machine

This Wanfur’s auto metal vibration welding machine can largely reduce your cost by 3 times more than other same industry. It is to weld copper and aluminum and is used for welding new energy batteries.

This metal vibration welding machine can save 30% cost compared same function machines: Specifically designed for copper and aluminum products welding and design, different metal parts can share the same welding machine, as it can be quick to change the fixture production, automatic loading and unloading, can do an average of 10s/set, and effectively improve production efficiency and labor efficiency, reducing production costs.

This metal vibration welding machine can save 30% cost compared same function machines: Specifically designed for copper and aluminum products welding and design, different metal parts can share the same welding machine, as it can be quick to change the fixture production, automatic loading and unloading, can do an average of 10s/set, and effectively improve production efficiency and labor efficiency, reducing production costs.

Fully Servo Vertical Vibration Welding Machine (Rotary Friction Welding)

Equipment Description

This friction welding equipment is designed for welding copper and aluminum products, with support for multiple product types on a shared platform.

Key Features:

Quick fixture change for different production models

Automatic loading/unloading of materials

Real-time monitoring of displacement, pressure, temperature

Displays historical curves, supports data traceability

Auto-detection of abnormal process data & welding size deviation

Welding Quality Management System:

Imports process data packages

Connects to MAS (Manufacturing Automation System) for full integration

Equipment Parameters

| Parameter | Specification |

|---|---|

| Project | Fully servo vertical friction welding equipment (rotary friction welding) |

| Voltage | 380V |

| Power | 270KW |

| Compressed Air Pressure | 0.5 – 0.8MPa |

| Machine Size | L780 × W1050 × H2180 mm |

| Machine Weight | 1000KG |

| Control System | Mitsubishi / Inovance |