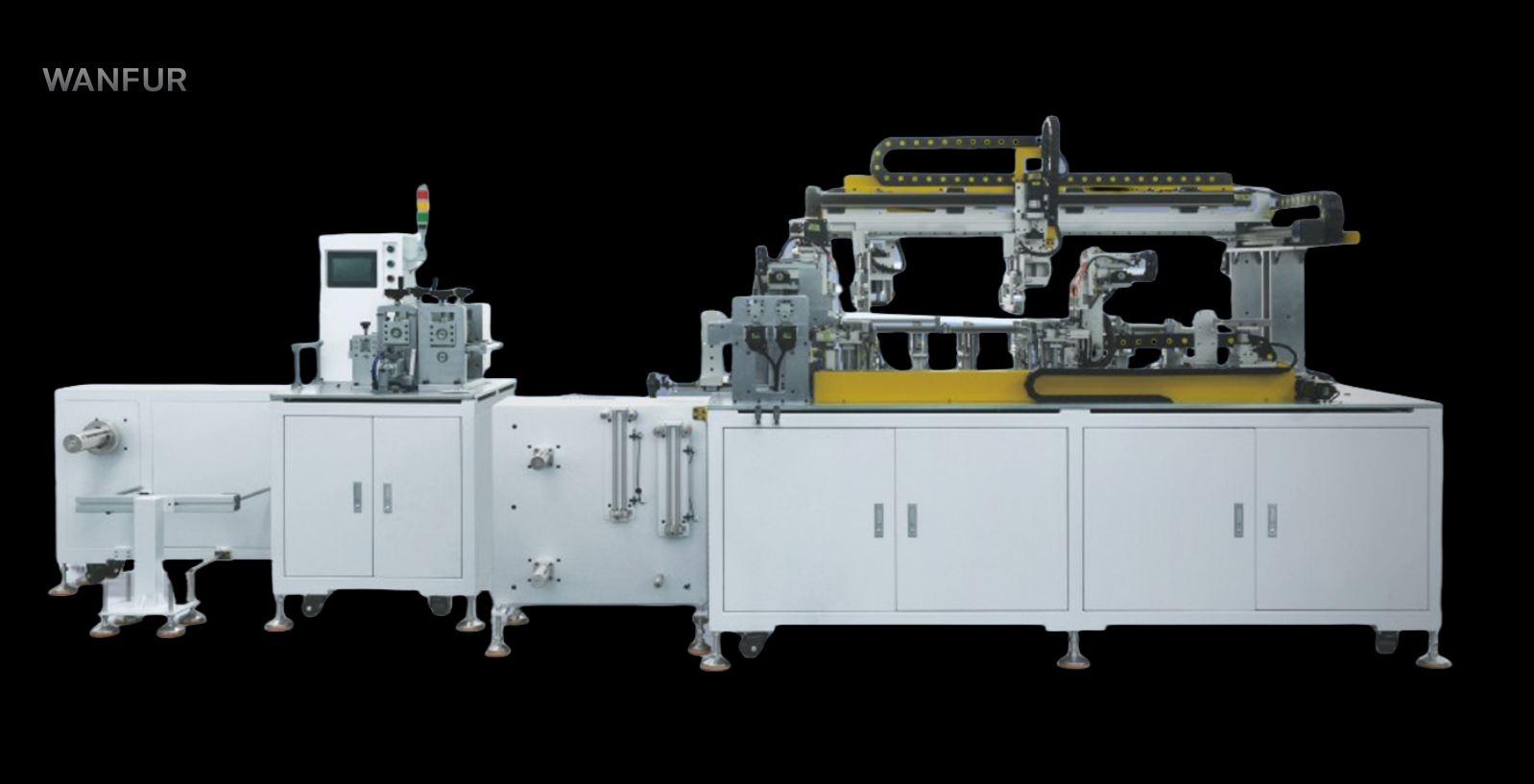

Soft Busbar Automation

Integrated Automatic Production Line for New Energy Copper/Aluminum Busbars

Equipment Description

This project is designed for the automatic production of copper and aluminum busbars. The process is fully automated from bending to peeling, cutting, and punching, ensuring a seamless and efficient manufacturing flow.

After the busbars are bent, a robot:

Transfers them to an automatic peeling machine

Then places them on the assembly line for further cutting and punching

Fully automated workflow – no manual operation required

High efficiency and improved production consistency

Stabilizes entire production flow, increasing yield and reducing errors

Suitable for mass production of copper/aluminum busbars

Significantly reduces labor costs and production expenses

Equipment Parameters

| Parameter | Specification |

|---|---|

| Project | Integrated automatic production line for new energy copper bars |

| Voltage | 380V |

| Power | 25kW |

| Compressed Air Pressure | 0.5 – 0.8 MPa |

| Machine Size | According to the actual situation on site |

| Machine Weight | Approx. 13T |

| Control System | Mitsubishi |

| Robot Brand | Kawasaki / Topstar |