Bespoke Automation

We specialize in delivering bespoke automation solutions that cater to diverse industrial needs. Our expertise ranges from designing and manufacturing simple, standalone poka yoke mechanical devices to creating fully automated production lines. Our goal is to enhance Overall Equipment Effectiveness (OEE), efficiency, and productivity for our clients. By leveraging cutting-edge technologies and our wealth of experience, we provide innovative and customized solutions that address specific challenges in industrial automation. Whether it’s streamlining processes, reducing errors, or optimizing workflow, our bespoke solutions are designed to meet the unique requirements of each client, resulting in improved operational performance and increased competitiveness.

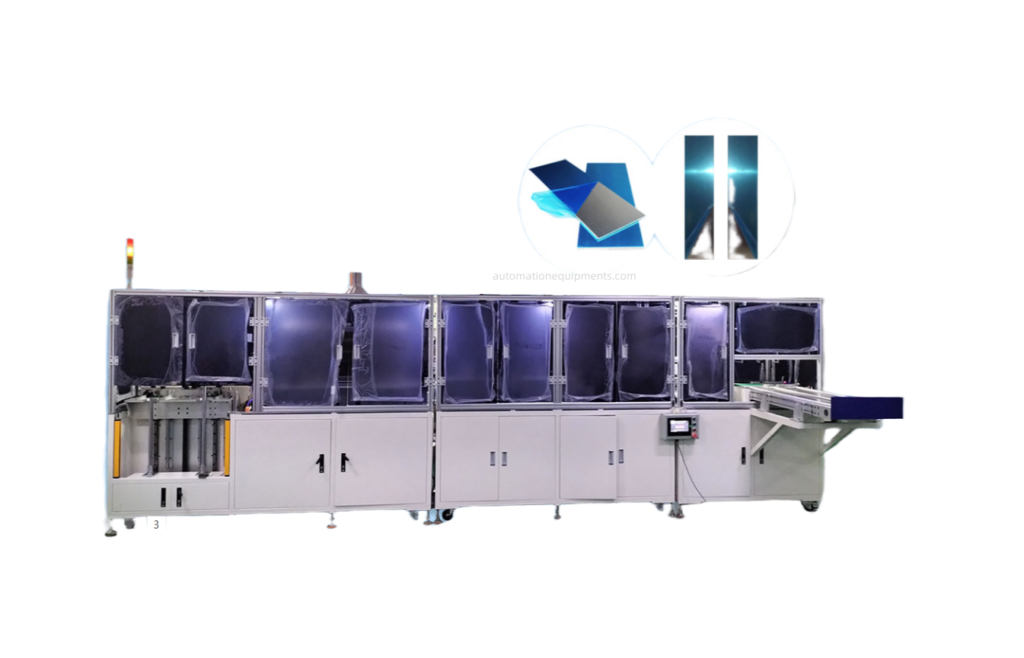

New Energy Vehicle Battery Tray Film Removal Production Line

Film Removal Speed: 12 cm to 15 cm per second. [Fast speed, high efficiency, capable of double-sided film removal.

The New Energy Vehicle Battery Tray Film Removal Production Line is a cutting-edge system designed for efficient removal of film from battery trays. With a remarkable film removal speed ranging from 12 cm to 15 cm per second, the production line operates at a fast pace. Its high efficiency enables swift and effective film removal, contributing to streamlined manufacturing processes. Additionally, the system is capable of performing double-sided film removal, further enhancing its versatility and productivity. This advanced production line offers fast speed, exceptional efficiency, and the ability to handle film removal from both sides, making it an ideal solution for the New Energy Vehicle industry.

Fully automated keycap assembly production line

It can assemble an average of five keyboards per minute. Automatic feeding, automatic assembly, automatic packaging.

The fully automated keycap assembly production line is a state-of-the-art system that excels in efficient keycap assembly. With the capability to assemble an average of five keyboards per minute, it ensures high productivity. The line is equipped with automatic feeding, enabling seamless transfer of components. The process of assembly is completely automated, eliminating the need for manual intervention and ensuring consistent quality. Furthermore, the system includes automatic packaging, streamlining the final stage of product preparation. With its comprehensive automation features, this production line offers fast and efficient keycap assembly, leading to increased productivity and improved operational efficiency.

Buyer’s Guide:

We believe in giving you the freedom to make decisions that work best for you. Here are some recommendations to consider when purchasing our products.

Budget: Determine your budget for the machine you want to buy. Research products available within your budget range. We assure you that we offer the best products within your budget.

Customer Reviews: Check customer reviews, both positive and negative, to get an idea of the satisfaction level of our products. If you find everything satisfactory, proceed with the purchase. We are always here to assist you.

Follow these 9 simple steps to buy from Hongchang:

- Consultation: We will discuss your requirements through a presentation file or a meeting via Zoom/Teams, also can visit customer plant for more detailed discussion.

- Quotation: We will provide you with a detailed quotation, including the best parts, accessories, jigs, robots, and affordable prices.

- Process Evaluation: Both parties carefully evaluate technical parameters, specifications, and business terms to avoid any misunderstandings.

- Placing Order: If you are confident, we will send you a Proforma Invoice (PI) and sign a contract with you.

- Production: Once we receive your contract and deposit, we will start the production of the automation equipment. We will keep you updated on the production progress.

- Inspection: The production process undergoes regular inspection and strict quality control. The machines are thoroughly tested before leaving the factory.

- Delivery: We will arrange the delivery as agreed upon in the contract.

- Custom Clearance: We will provide all necessary shipping documents and ensure a smooth customs clearance process.

- Support and Service: We offer professional technical support and 24/7 customer service through various channels like Phone, Email, Skype, WhatsApp, WeChat, and Remote Service. We are committed to providing you with the best support and assistance throughout the buying process.