Advanced Busbar Processing Solutions

Fully automated solutions for copper and aluminum busbar processing with precision and efficiency

Precision Engineering

Handles busbars from 0.5m to 2.5m with guaranteed dimensional stability and exceptional accuracy

Robotic Synchronization

Advanced robotic systems follow bending machine’s motion for seamless, automated workflow

Enhanced Safety

Prioritizing operator safety while eliminating manual errors and improving production efficiency

Our Flagship Products

State-of-the-art busbar processing machines designed for the new energy vehicle industry

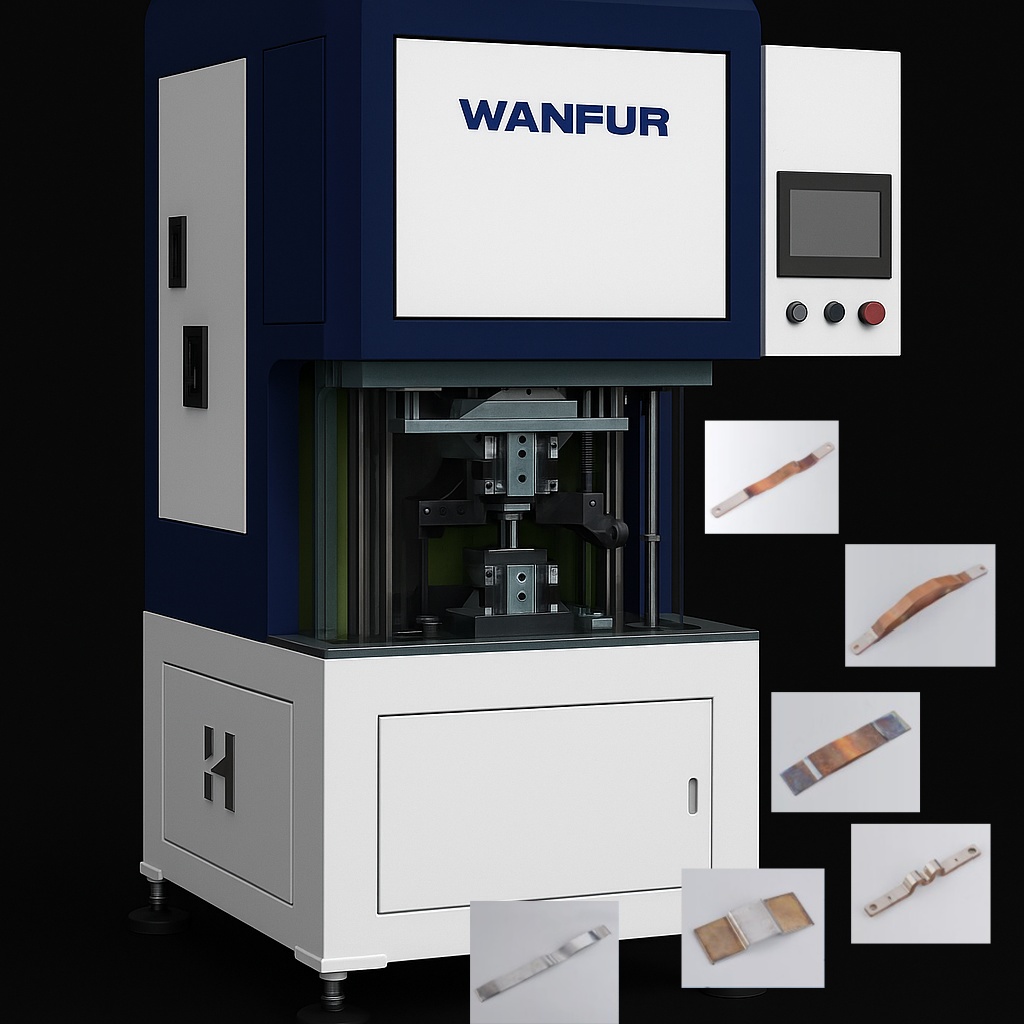

Busbar and Flexible Conductor Welding Machine

✅Busbar expansion joints

✅Soft connection conductors between: Soft busbars, Soft busbars and hard wires, Hard busbars

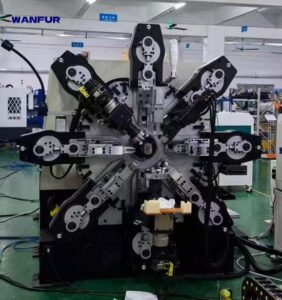

Busbar Processing Automation

✅Fully automated workflow with no manual operation required

✅Significantly improves efficiency and productivity

Friction Stir Welding Machine

✅fully automatic solid-state friction stir welding machine

✅compatible with laser cutting and CNC cutting.

Why Choose Wanfur

Leading the future of busbar processing and automation with proven expertise

Over 15 Years of Experience Focus on Busbar Processing Machines Manufacturing

Made Many Busbar Processing Machines for New Energy Vehicles

Professional Design and Technical Team Tailored for Your Busbar Processing Solutions

Genuine Softwares and Spare Parts with International Technology

24/7 One-To-One Expert Customer Service and Technical Support

Leading the Future of Busbar Processing

In an era where clean, efficient energy drives the global market, Wanfur stands at the forefront of innovation with our comprehensive suite of busbar processing machines. Trusted by top manufacturers in the new energy vehicle industry, our equipment delivers unmatched precision, speed, and reliability—helping you stay competitive in a rapidly evolving world.

Our flagship Busbar Bending machine, Peeling Machine, Welding Machine, Cutting Machine, Punching Machine, Winding Machine, Machining Machine… and Automation set new standards for accuracy and performance, ensuring smooth, consistently high-quality results for every project. Backed by advanced Busbar Processing Automation, these machines are designed to reduce labor requirements while increasing production throughput—vital factors in meeting the rising demands of electric and hybrid vehicle manufacturing.

Ready to Upgrade Your Busbar Manufacturing?

Contact our experts today to discuss how our automation solutions can transform your production process

News

Stay updated with our innovations and industry insights